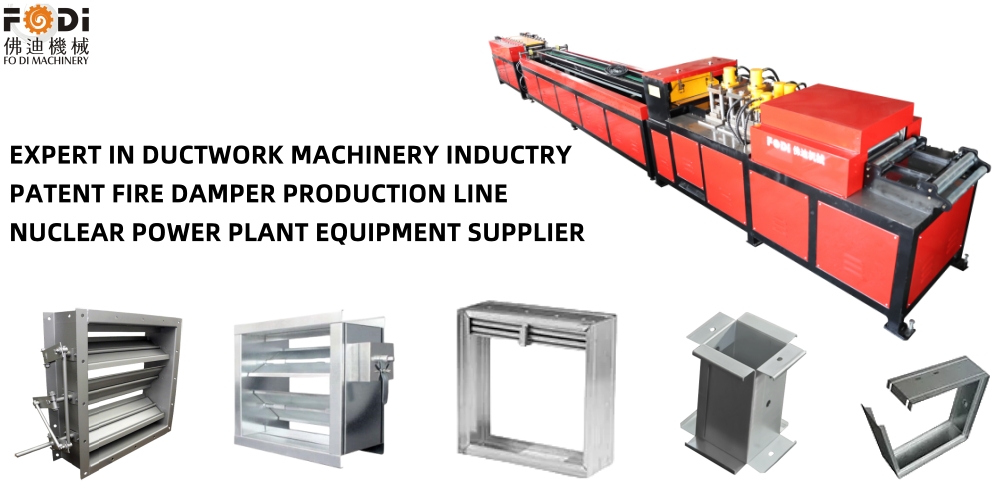

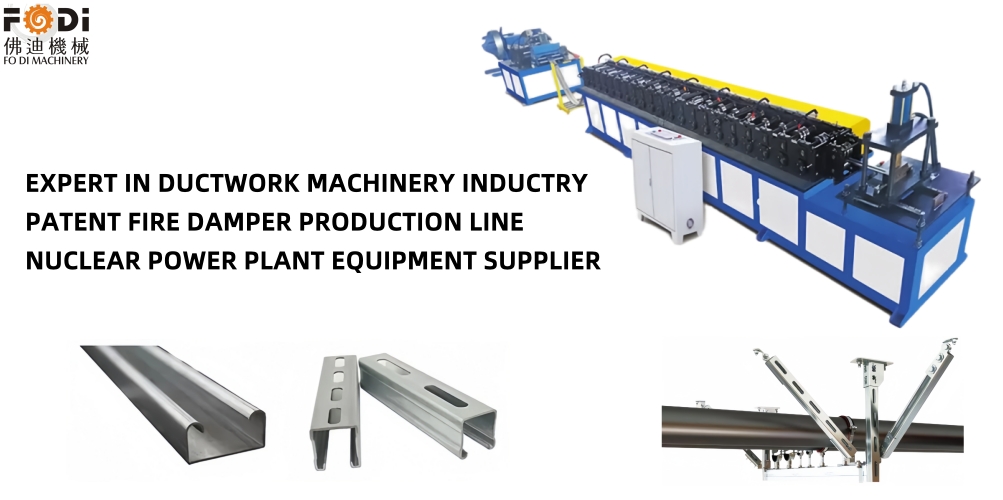

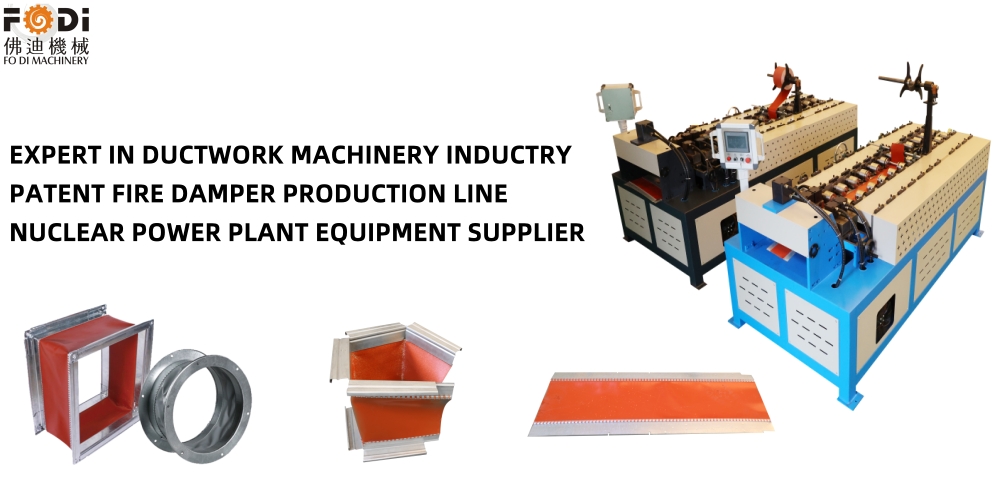

Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

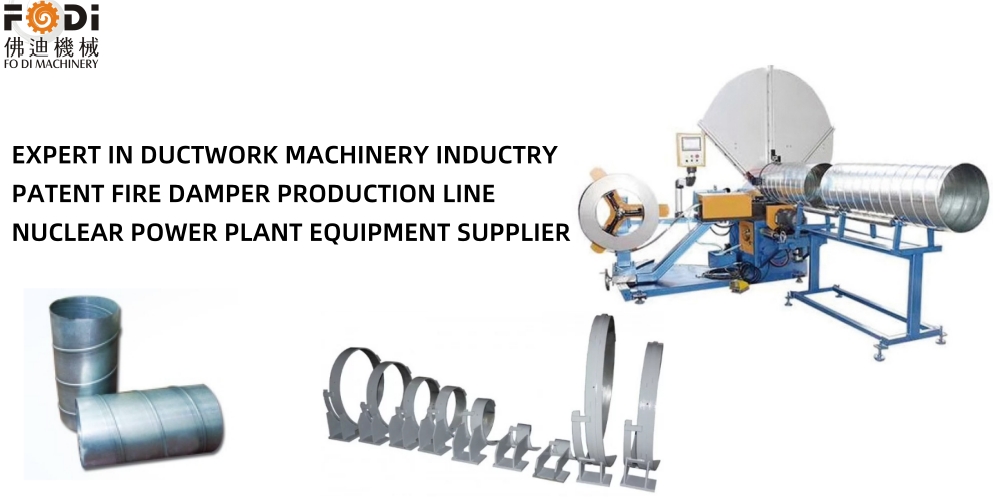

Spiral tubefomer

The spiral tubeformer is divided into molding type and steel strip type . The molding of corresponding size must be used for each size of spiral air pipe. For the steel strip type,adopt different specifications and lengths of steel strip, can process the corresponding size of air duct.

Spiral Tubeformer Aluminum Mold Type

Cutting method is roller cutting,no spark,no burr,no noise with smooth surface.Using three sets of forming wheels,the mold is aluminum alloy with fast forming speed, stable performance and fast mold changing High production efficiency. The air duct made of small air supply resistance, high strength and good sealing performance.

In a given processing of the diameter of the spiral duct diameter scope, the need for pipe die, using different lengths of steel belt, through the proper installation and debugging steel band instead of pipe die. The diameter of the product determines the speed of production, the smaller the diameter, the faster the production speed, on the contrary, the larger the diameter, the slower the production speed, because of the large diameter of the spiral duct, the load on the machine is higher. The length and can be used according to demand, and high-speed synchronous automatic cutting system for cutting. Due to the aesthetic appearance of this duct, this machine has also received considerable attention and many customers have given such machines a high rating. The spiral air duct forming machine is mainly used for making round spiral air duct. The machine can automatically complete round spiral tube with different diameters and different lengths based on customers demand. Fodi company adopts the principle of using duct mold to form the spiral duct. Spiral duct machine is easy to operate and fast to form duct with accurate diameter. The spiral duct forming machine needs to be used with round elbow machine, angle steel round rolling machine and etc, to complete the other work steps needed in spiral duct processing, Fodi company produces spiral duct forming machine and round elbow machine, angle steel round rolling machine and other equipment with high quality, also ensure that the pipe size processed out of precise appearance beautiful. So it can effectively help customers greatly improve the competitiveness of their products, Spiral duct machine has always been the most important equipment for round spiral duct. In order to make our products more competitive, we have optimized the structure of the machine for many times to make our machine has been greatly improved in speed and molding effect, and it has won unanimous praise from customers all over the world.

The module technique gives the customer the possibility to choose between a number of options, allowing him to create a machine a number of options, allowing him to create a machine for his specific needs. The frequency controlled main drive ensures a smooth acceleration and an almost noiseless operation. The outstanding patented flying slitter cuts the tubes to lengthwithout noise or hot sparks as known from the saws and provides smooth tube ends without deburring.

The design and options fulfill the needs in HVAC to produce in mild steel, galvanized steel, stainless steel or aluminum

The corrugation unit allows a reduction in material costs and makes the bigger diameter tubes more rigid.

Technical data

Diameter | ¢80 mm – ¢1600mm | |

Thickness range | Galvanized steel | 0.4 -1.3mm |

Stainless steel | 0.4-0.8mm | |

Aluminum | 0.4-1.3mm | |

Strip width | Standard 137mm | 0.4-1.0 mm |

Standard 140mm | 1.1-1.3 mm | |

Lock seam | Outside lock seam, on the inside on request | |

Working speed | Max.60 m/min. depending on material | |

Cutting system | Slitting cutter | |

Weight | 2900kg | |

Dimension | Main machine | 1900*2050*1500mm |

Decoiler | 1780*1130*1250mm | |

Run-out table | 2700*950*1200mm | |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|